Our Definition:

Real-Time Process Measurement and Control

optek's in-line process absorption and scattered-light

photometers utilize principals based on the interaction

of light with process fluids or gases. These unique

instruments provide precise, real-time process stream

analyses when installed at strategic locations within

the plant in pipelines, fermenters, reactors, tanks and

vessels. Typical applications include process

measurements of solids, liquids or gases to detect or

measure constituent concentrations, trace contaminants,

interfaces between products, quality assurance analyses

and a spectrum of other beneficial measurements, all in

real-time with impressive precision and reliability.

optek photometric analyzers consist of three main

assemblies:

- Converter (transmitter)

- Sensor - in-line flow-through or

insertion-type probe sensor bodies equipped with

light source and detector assemblies.

- Cableset - special high-grade shielded

cable assemblies interconnecting the sensor to the

converter.

Within the sensor, light from the light source is

focused and sent into the process stream. The emerging

light that has penetrated the process medium is

precisely filtered then measured on the opposing side by

high-precision absorption or scatter-light detectors.

The resultant photocurrents from the process sensor are

precisely amplified, analyzed and converted by the

transmitter and then sent to the plant's process control

system providing real-time measurements in virtually any

unit of measure.

PRINCIPLES OF MEASUREMENT

optek process photometers utilize two principles which

are based on the interaction of light that is passed

through process liquids and gases:

-

Light Absorption

-

Light Scattering

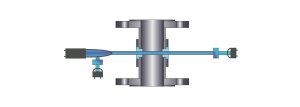

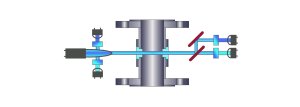

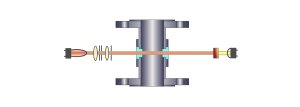

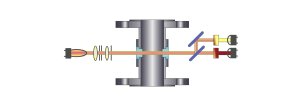

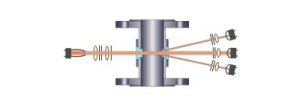

For an example of these

two principles, the illustrations below show cutaway

views of typical flanged in-line type sensors. Please

note on the left side of each illustration a light

source, apertures and focusing optics are depicted as

sending light through the process medium via two windows

installed in the in-line sensor body. The light travels

through the process medium and is detected on the

opposing side by a variety of optical configurations.

Each of the illustrations

depict the orientation of photo detectors and optics in

relation to the incident light source on the opposing

side of the sensor body. Each design has specific

applications and benefits for the measurement of liquids

and gases in-line and in real time.

UV -

Ultraviolet Light Absorption

Single

Channel Light Absorption

(single detector, with lamp reference detector)

Dual Channel Light Absorption

(beam splitter, dual detectors and dual lamp reference

detectors)

VIS

/ NIR - Visible and Near Infrared Light Absorption

Single Channel Light Absorption (single

detector)

Dual

Channel Light Absorption (beam splitter, two

detectors)

Scattered-Light - 11° Forward

Dual Beam Light Scatter (one reference

detector and eight 11° scatter detectors)

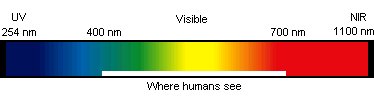

optek's Spectral Range of Measurement

Wavelengths: 254 nm (Ultra Violet) to 1100 nm (Low Near

Infrared)

The complete line of

optek process photometers use two superior grade light

sources and a variety of precision filters and photo

components. The wide selection of optical components

allows optek to configure a process analyzer to measure

within a specific portion of the electromagnetic

spectrum to serve a host of specific process measuring

applications:

optek light

Sources:

Low Pressure Mercury: Measuring Range: 254 to

340 nm

Full Spectrum Tungsten:

Measuring Range: 380 to 1100 nm

Lambert-Beer Law

Lambert Beer’s

law is a mathematical means of expressing how light is

absorbed by matter. The law states that the amount of

light emerging from a sample is diminished by three

physical phenomena:

- The amount of

absorbing material in its pathlength (concentration)

- The distance the

light must travel through the sample (optical

pathlength OPL)

- The probability that

the photon of that particular wavelength will be

absorbed by the material (absorptivity or extinction

coefficient)

This relationship may be

expressed as:

A = ebc

Where: A= absorbance; e =

molar extinction coefficient; b = pathlength in cm; and

c = molar concentration.

Transmittance

As a beam of light passes

through an absorbing medium, the amount of light

absorbed in any unit volume is proportional to the

intensity of incident light times the absorption

coefficient. Consequently, the intensity of an incident

beam drops exponentially as it passes through the

absorber. This relationship when expressed as Lambert’s

Law is:

T = 10-acx or T

= 10-A

Where T = transmittance;

a = absorption coefficient; c = molar concentration of

the absorber and x = pathlength in cm

In a simplified approach,

the transmittance can be expressed as the intensity of

the incident radiation, Io which is ratioed to the light

emerging from the sample, I. The ratio I/Io is referred

to as transmittance or simply T.

Absorption

Transmittance can be

plotted against the concentration, but the relationship

is not linear. The negative log 10 of the transmittance

is, however, linear with the concentration.

Therefore, absorption is

measured as:

A = -log 10 (I/Io) or A = -log 10

(T) |